一、About track-etched membrane

Track-etched membrane is the use of thermal neutrons in nuclear reactors to fission uranium 235, fission debris through the organic plastic film, leaving a narrow radiation damage channel in the path of fission debris. The channels are oxidized and etched with appropriate chemical agents to turn the channels on the film into cylindrical micropores. Nuclear pore films with different pore densities and pore sizes can be obtained by controlling the irradiation and etching conditions of nuclear reactors.

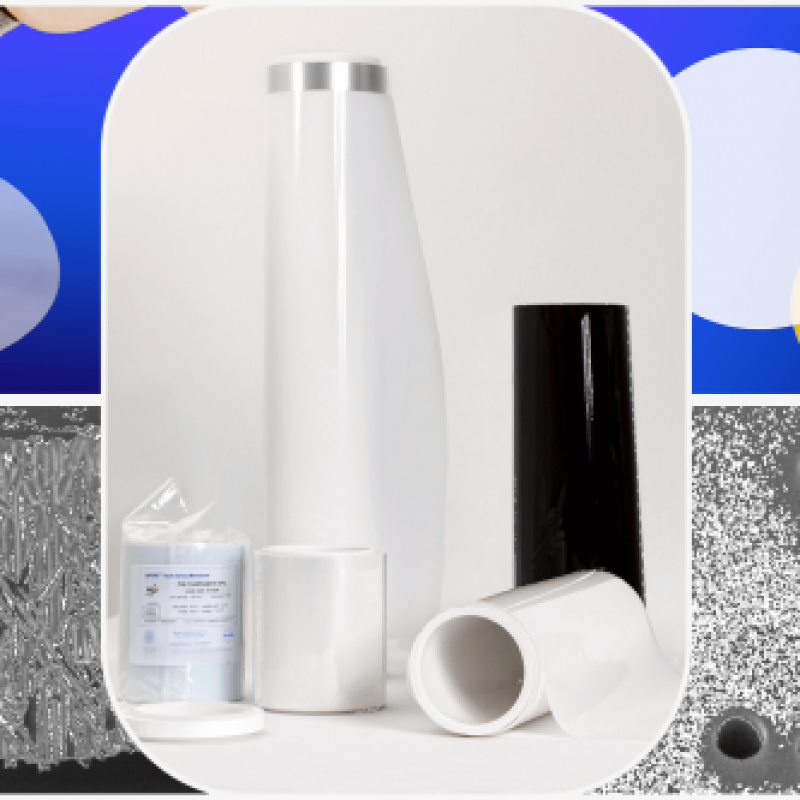

The material of the nuclear pore film is a variety of insulating solid film, commonly used polycarbonate (PC), polyester (PET), polyimide (PI), polyvinylide fluoride (PVDF), etc., polycarbonate is currently the most used material, high etching sensitivity, etching speed, can make a small pore membrane, the minimum pore size of 0.01μm. For example, the Belgian it4ip nuclear pore membrane has a pore diameter of 0.01-30μm nuclear pore membrane, and has the technology to produce polyimide nuclear pore membrane. SABEU produces nuclear pore membranes with pore sizes of 0.08-20μm in polycarbonate, polyester and PTFE for medical use.

The nuclear pore membrane has a regular geometry, uniform aperture, and is basically a cylindrical through hole. When filtering, particles larger than the aperture are trapped on the surface of the filter membrane. It is a dielectric film, and there is no pollution of the filtrate by the filter membrane itself, and it is an ideal tool for precision filtration and particle screening. The nuclear pore membrane has high mechanical strength, good flexibility and can withstand repeated washing, so it can be reused many times.

二、Basic parameters of track-etched membrane

The pore size, pore length (thickness) and pore density of the nuclear pore membrane are the basic parameters. The pore size is determined by the etching time. By controlling the chemical etching time, the nuclear pore film with specific pore size can be obtained. A precise nuclear pore membrane with narrow pore size distribution can be obtained during the fixed etching process, which provides accurate filtration values and can efficiently and accurately exclude particles during filtration, suitable for strict filtration operations, such as templates for the synthesis of nano or micron materials, for the filtration separation of cancer cells, etc.

The pore density is equal to the number of heavy ions irradiated vertically on the film per unit area, and the nuclear pore film with specific pore density can be obtained by controlling the flow rate of heavy ions. By adjusting the beam, the hole density can be obtained from 1000 holes per square centimeter to 1E+09 holes per square centimeter. Commonly used porosity represents the size of the pore density, and porosity refers to the ratio of the total area of micropores to the distribution area of micropores. If the pore density is too large, the reporosity will increase significantly, which will destroy the unity of the pore size, and the porosity is generally less than 10%. it4ip can provide nuclear pore film with a porosity of about 40%.

The length of the nuclear pore film or the thickness of the nuclear pore film is related to the type of material, the type of heavy ion nuclide and the energy. The thickness of the nuclear pore film made of fission fragments is equal to or less than 10μm. The heavy ion energy produced by the heavy ion accelerator is higher, and the thicker nuclear pore film can be made. The thickness is larger, the mechanical strength is larger, and the speed of liquid and gas passing through the nuclear pore membrane is also smaller.

By selecting pore size, pore density and filter membrane thickness, nuclear pore membranes with specific water and air flow rates can be produced.

In addition to the above basic parameters, the gap arrangement is also an important parameter of the nuclear pore membrane, in addition to the vertical 90 degree hole, there are multiple Angle holes, such as parallel inclined holes, cross plus or minus 45 degrees. For example, a template for a 3D interconnected nanowire network is synthesized using a track etched membrane filter with a +45°/-45° hole.

三、Comparison of track-etched membrane and cellulose membrane

There are many kinds of microporous membranes used in the laboratory and industry, commonly used is curved membrane, also known as chemical membrane or cellulose membrane, the microporous structure of these membranes is irregular, similar to plastic foam, the actual pore size is relatively dispersed, and the nominal pore size of the nuclear pore membrane is the same as the actual pore size, the pore size distribution is narrow, can be used for accurate filtration.

Nuclear pore membrane is very different from cellulose membrane, nuclear pore membrane is better than cellulose membrane in many aspects, the main advantages are:

· Good retention characteristics. The pore size of the nuclear pore membrane is regular and uniform, and the particles larger than the pore size can be accurately trapped, and the particles larger than the pore size can be trapped on the filter surface for separation. The pore size of the mixed cellulose ester filter membrane is dispersed around the average value, so the retention is poor.

· The nuclear pore film is transparent, the surface is flat and smooth. Such a membrane is conducive to collection and particle analysis by means of an optical microscope. For microbial observation, the surface of the membrane can be directly stained without the membrane itself being stained, which is conducive to fluorescence analysis.

· High filtration speed. Although the porosity of the nuclear pore film is low, the thickness is thin. Although the mixed cellulose ester film has a high porosity, it is thick, and the channel is curved and the size is uneven. The filtration speed is not as good as that of the nuclear pore film.

· High mechanical strength, good flexibility. The tensile strength of polycarbonate and polyester pore membrane is greater than 200㎏ / ㎝2, and the mixed cellulose ester filter membrane is far less flexible than the pore membrane.

· Good chemical stability. The nuclear pore film can resist acid and most organic solvents etching, its chemical stability is better than mixed cellulose ester film.

· Good thermal stability: the nuclear pore film can withstand 140 ℃ high temperature without affecting its performance, so it can be repeatedly hot pressed disinfection without cracking and deformation, and the mixed cellulose film can withstand 120℃. The low temperature also has no significant effect on the properties of nuclear pore film.

· Good biological characteristics: the nuclear pore membrane is neither antibacterial nor bactericidal, nor is it subject to microbial erosion, with the help of appropriate media, bacteria and cells can grow directly on the filter membrane, and can work in humid conditions for a long time, while the mixed cellulose ester is not.

· The nuclear pore membrane has no particles, fibers, etc., and will not pollute the filtrate like other filter papers. It can be made into hydrophobic film (for air pollution monitoring, etc.) hydrophilic film.

· Light weight, good weight consistency, low water absorption, less ash, the film is not susceptible to moisture deterioration, while the mixed cellulose film is susceptible to wet deterioration.

Application of track-etched membrane

The nuclear pore membrane has a precise and uniform pore diameter, which is ideal for accurately retaining small particles and can be used in filtration technology, laboratory analysis, medical, pharmaceutical, chemical, food, cell biology, microbiology, nanotechnology and automotive electronics.

1, gas liquid filtration

Nuclear pore membrane can filter solid substances in liquids and gases, such as bacteria, viruses and other granular impurities, for air purification, ultra-pure gas or reagent preparation, medical filtration and disinfection. For example, SABEU membrane is used for Legionella detection. Recycling of bacteria in food, beverages and cosmetics.

Sterile exhaust for use in life science and medical environments protects both the laboratory environment from microorganisms and live microorganisms from external contamination, ensuring that no microorganisms enter the patient through contact with medical equipment, and the opening to the outside is equipped with sterile air filters to protect the environment from potential contamination. The TRAKETCH microporous filtration membrane provides a reliable barrier, is biocompatible with USP Class VI, is suitable for a variety of sterilization environments, and the flat, smooth surface also allows liquids to form droplets and flow out of the membrane, thus keeping the membrane dry and ensuring sterile air discharge.

Protection of patients and medical equipment: Disposable products used to protect patients and medical devices, such as air vents, hearing devices, sensor protectors and intravenous infusion sets, TRAKETCH microporous filtration membranes have precise holes for sterile ventilation and USP grade toxicity testing, are biocompatible according to FDA standards, are ultra-clean, non-falling off, extractable and other features.

Liquid drug filtration: The injection cannot contain solid particles larger than 3.5μm, and the nuclear pore membrane can ensure the high-quality filtration of the injection. Nuclear pore membranes prevent particles or bacteria from entering the body, and SABEU’s PFOA-free nuclear pore membranes, especially without fiber shedding, are suitable for use in infusion and drug delivery systems.

2. Medical diagnosis field

For the recovery of cervical cancer cells, separation of circulating cells, cell counting by flow cytometry, fluorescence microscopy, etc.

For example, the nuclear pore membrane is used for Pap tests in thin-layer cytology, which can effectively recover cells. For liquid-based thin layer cytology (TCT screening) to recover cervical cancer cells. It4ip nuclear pore membrane for ocular diagnostic cytopathology, excellent cytological preparation, no background staining, only a small fluid sample, useful for eye fluid samples, such as aqueous humor, vitreous specimens, and corneal and conjunctival scrapes.

3. Life Sciences

Including cell culture, cell isolation and detection. Such as the culture of polarized animal cells, the development of cell culture embedment dishes and so on. Also used in ICCP – Interactive Cell Co-culture plates, ideal for intercellular communication studies, exosome studies, immunology studies, regenerative medicine studies, co-culture studies, and immunostaining studies.

For example, for the culture of lung cells and tissues, unlike spongy membranes, TRAKETCH nuclear pore membranes do not allow cells to enter the material and adhere to the pores, but grow on a flat and smooth surface. Without damaging the tissues, the tissues can be easily peeled off for inspection or further use. This principle is conducive to the culture of transplanted skin cells. SABEU nuclear pore membranes are also used in the cosmetic and pharmaceutical industries for skin model experiments on track etched membranes.

4. Automotive electronics

Automotive vehicle exhaust: The TRAKETCH® ion track membrane has an IP rating of 67 or 68 and is ideal for filtering liquids and particles for these mechanical and electrical components due to its precise porosity.

Protection of sensitive electronics: Compared to other membranes, TRAKETCH® ion orbital membranes have a uniform aperture and uniform airflow. It is also hydrophobic and oleophobic. These properties protect sensitive electronics used outdoors and in humidity, protecting electronics from particulate matter while maintaining permeability to air.

Pressure Compensation Element: The pressure Compensation element (PCE) consists of a hydrophobic and oleophobic filter membrane (PFOA free) that compensates for the resulting pressure changes while blocking external moisture and particles. Used in a variety of electronic products, lighting systems, packaging and electronic medical equipment.

5. Nanotechnology

Templates for the synthesis of nanomaterials, such as self-supporting three-dimensional interconnected nanotubes and nanowires

The orbital etched film is used as a multifunctional template processing method for growing large three-dimensional interconnected nanowires or nanotube arrays that are easy to adjust geometrically and spatially.