Welcome to Dalian Leader Laboratory, a provider of laboratory solutions!

Service hotline: 0411-87307760

中文

中文

Welcome to Dalian Leader Laboratory, a provider of laboratory solutions!

Service hotline: 0411-87307760

中文

中文

一、 Elveflow company introduction

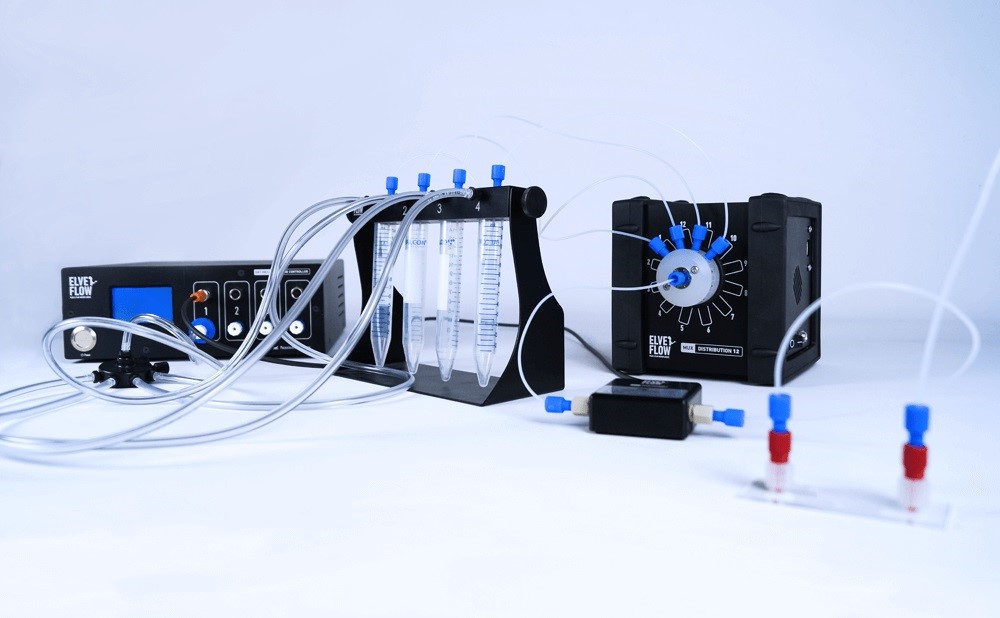

Elveflow France has been manufacturing quality microfluidic processing instruments since 2012, and to date, we have delivered up to 2,000 systems to scientific and industrial users. Our products are built around the best-selling OB1 flow controller and include a complete set of components for liquid handling. Our instruments can be controlled using both our software and software development kit to fully automate your system. Our instruments are modular, upgradeable and available in standard and OEM versions. Products include microfluidic multi-channel pressure vacuum controllers, rotary distribution valves, flow switches, valves and valve controllers, flow sensors, pressure sensors, sensor readers, bubble detectors, reservoir tubes and microfluidic applications.

二、Elveflow microfluidic products

1, OB1 multi-channel pressure vacuum controller

The OB1MK4 is a high-performance microfluidic pressure and flow controller. Elveflow's best-selling product controls the speed of microfluidics through pressure and vacuum regulation. The OB1 allows individual control of the output pressure of up to 4 channels, from -900 mbar to 8 bar, for a variety of advanced microfluidic applications. Thanks to advanced piezoelectric technology, OB1 is 10 times more stable and 10 times faster than other microfluidic flow controllers. It is the pressure and vacuum pump on the market with rapid response speed and accuracy

The standard multi-channel pressure and vacuum controller has 4 channels, each channel has 5 optional pressure ranges, with modular upgradable tape software features, can be customized according to the actual needs of customers more channels and application scenarios.

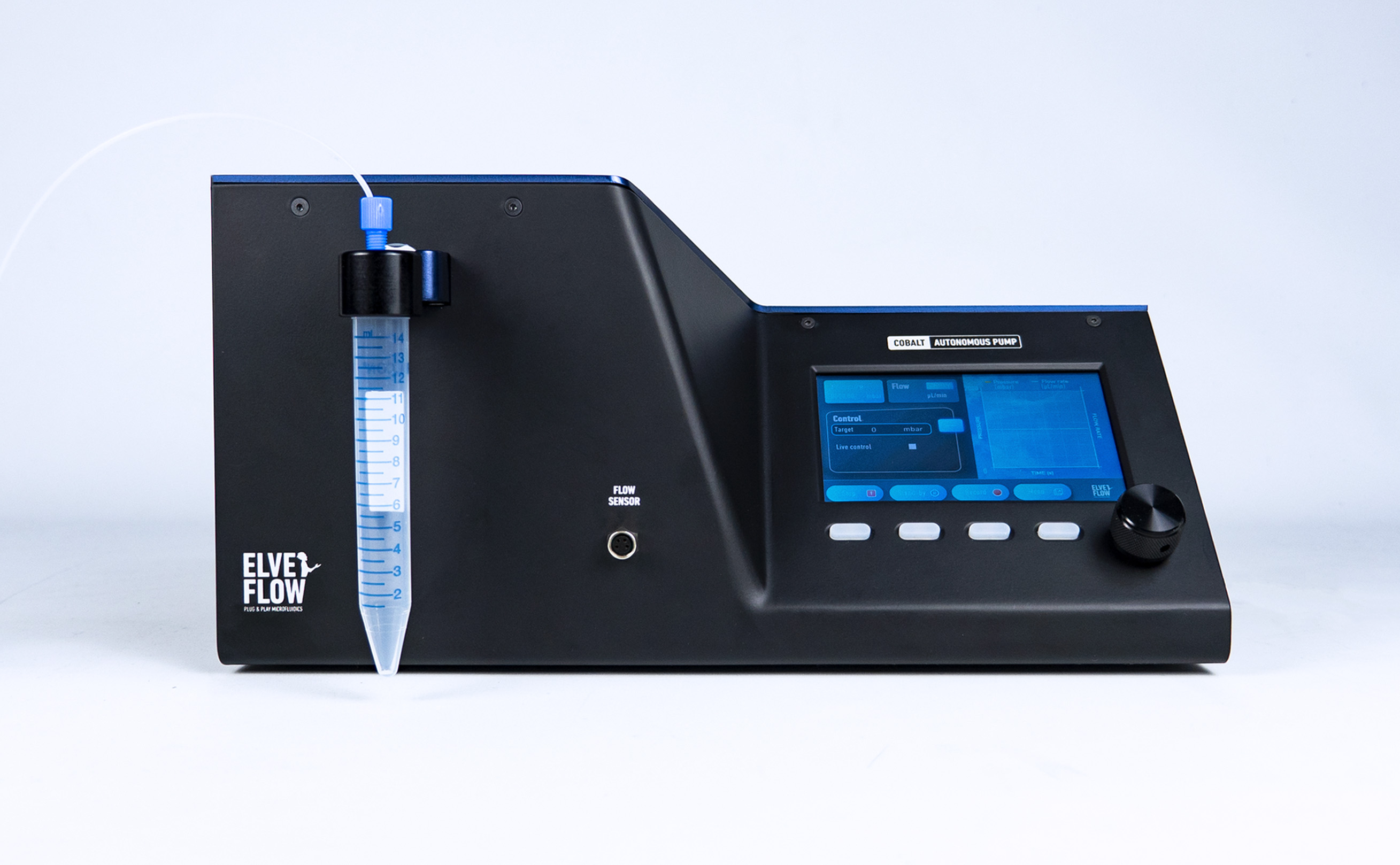

2. Cobalt single channel pressure controller

Cobalt is a portable single channel pressure or vacuum controller to replace the original AF1, which has good fluid performance compared to injection pumps and peristaltic pumps, capable of stable microfluidic delivery with low pulsation and high precision.

Cobalt is a self-contained and autonomous pressure & vacuum pump, Cobalt comes with its own pressure (vacuum source) and does not require an external compressor or laboratory gas supply. It is designed to minimize vibration and volume. It has an embedded user interface of the instrument itself, which can be controlled directly through the knob of the instrument interface without using external software.

3, microfluidic flow sensor

(1) MFS microfluidic flow sensor

The MFS thermal flow sensor is a high precision liquid flow sensor for low flow monitoring. The MFS flow sensor has a wide flow range of 0.07 to 5000µL/min with a corresponding time of 40ms, a resolution of 1.5pL/s, and high chemical compatibility. The flow sensor is used in conjunction with an OB1 pressure controller or sensor reader for direct flow control and forward and reverse flow rate measurement.

(2) BFS section flow sensor

BFS Coe Flow sensor A Coe flow sensor for microfluidics with a flow range from 1.6 μL/min to 500 mL/min, response time: 35 ms, the BFS features an accurate, wide flow range, from microliter to ml flow, compatible with liquids and gases, direct use without calibration, combined with the OB1MK3+ vacuum pressure controller and sensor reader for flow monitoring and control.

4, microfluidic pressure sensor

MPS Small volume pressure sensors for liquids and gases, compatible with 3/32" inner diameter lines or 10-32 connectors for 1/16" outer diameter lines, suitable for low flow pressure, for measuring and controlling pressure with accuracy of 0.2% FS, in 5 ranges from 70 mbar to 7,000 mbar, The internal volume is 7 μL and the stabilization time is 20 ms.

The MFP Luhr interface pressure sensor is suitable for gas or liquid use with standard Luhr interface. High chemical compatibility, pressure range 0-16 bar, MAX pressure 25 bar, no dead volume, flow up to 100 mL/min. Wide media compatibility (contact material: FFKM), FDA approved for the food industry. The pressure sensor can be connected to the desired position of the microfluidic device, the pressure can be recorded by the computer and the pressure or flow can be adjusted using our OB1 pressure pump.

5. Other microfluidic components

(1) MUX Distrib 12-pass bidirectional selection valve, a rotary valve designed for rapid liquid switching, as a selector, a liquid sample can be sequentially injected into 12 different pipelines, or 12 liquid samples can be sequentially injected into one pipeline. The microfluidic bidirectional rotation selection valve can be used to process multiple samples and automate experiments. Applications include on-chip cell culture, cell response due to culture medium changes, drug screening, toxicity testing, sensor testing & calibration, solvent switching in flow chemistry, etc.

(2) The MUX RECIRCULATION Unidirectional injection circulation valve is A 6-port / 2-bit microfluidic valve that allows switching between A/B positions for stable unidirectional fluid circulation and sample injection. Applications include on-chip cell culture, drug screening, toxicity testing, stem cell detection, organ-on-chip, SPR or TIR imaging combined with microfluidics, heat dissipation experiments, and more.

(3) MUX WIRE microfluidic valve and valve controller, valve has 2 or 3-channel low pressure valve and high pressure valve, valve controller can control 1 to 8 valves at the same time, easy to integrate. Multi-flow valves can also be customized according to customer needs, such as 4 into 1 out of the valve. The valve controller can be used to easily control microfluidic valves for rapid liquid switching, liquid sampling, stopping and continuing flow, and complex sequential injection, including flushing, rinsing, and sequential injection of several liquids.

Other components include MBD bubble detector, bubble catcher, reservoir pipe, pressure source, vacuum pump and various connector lines, providing a complete microfluidic system to meet customer needs

三、Elveflow microfluidic application suite

The application areas of Elveflow system include digital microfluidic, flow chemistry & polymer synthesis, cell culture, cell perfusion, sequential injection, droplet sequencing, organ-on-a-chip, increased oil recovery, lab-on-a-chip, etc. On this basis, the plug-and-play microfluidic application suite is launched for some specific applications, which is an integrated solution for microfluidic. Includes all the equipment needed to successfully run microfluidic experiments, out of the box, easy to use.

The Elveflow microfluidic application includes:

Microfluidic Startup kit: Basic kit for microfluidic experiments

Microfluidic microdroplet Generation Application Suite: out-of-the-box flow control and on-chip system for droplet generation

Microfluidic multi-liquid sequential injection package: Rapid injection of up to 13 fluids with the Mux distrib valve.

Microfluidic nano liposome Synthesis kit: Microfluidic system for nano liposome, solid liposome nanoparticle synthesis

Microfluidic liquid circulation kit: Used for unidirectional and long-term flow of liquid microfluidic chips and other devices

Microfluidic Organ-on-a-chip kit: Culture infusion and simulation of in vivo physiology for microfluidic cell chips

Microfluidic Live Cell Infusion kit: A pressure pump is used to inject a variety of liquids into a microfluidic chip