Welcome to Dalian Leader Laboratory, a provider of laboratory solutions!

Service hotline: 0411-87307760

中文

中文

Welcome to Dalian Leader Laboratory, a provider of laboratory solutions!

Service hotline: 0411-87307760

中文

中文

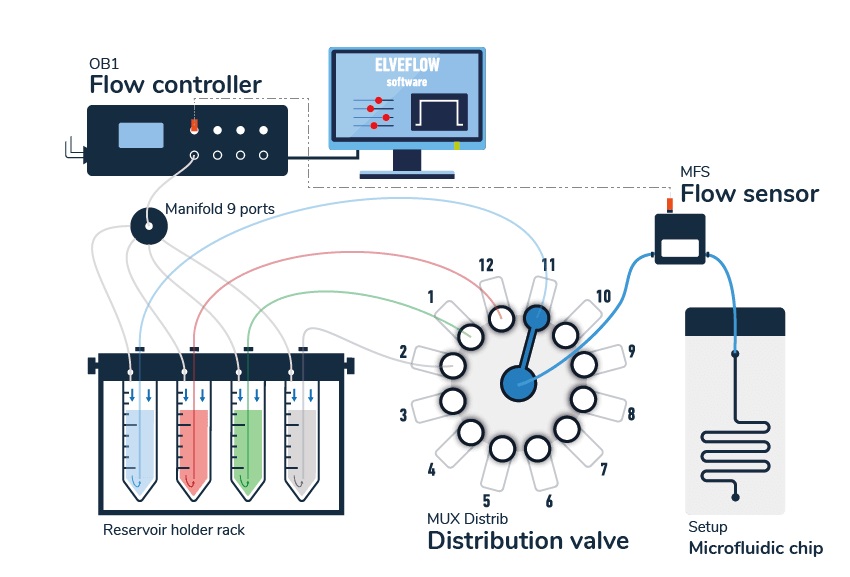

The Sequential Microfluidic Injection package is a system from France Elveflow for multiple fluid switching, allowing rapid switching of 12 or more liquids or gases at controlled flow rates. It can realize the injection of a variety of fluids, with high stability and accuracy, and belongs to the automation of microfluidic workflow. The system has strong versatility and can use a variety of fluids.

Elveflow's all-in-one flow control system for quickly switching fluids while maintaining flow. Multiple experiments or tests can be performed using one system at a time to automate multiple fluid injection/testing and save time.

Elveflow's sequential fluid injection systems are used in systems that require rapid exchange between multiple fluids while maintaining accurate flow rates. It is particularly suitable for complex organic chemical reactions, organic synthesis, biosensors, biochemical sensors or electrochemical sensors, test benches, flow chemistry, Seq-Fish experiments, analytical chemistry units, drug and toxicity testing, microsphere synthesis, organic catalysis experiments, and instruments for antibiotic resistance testing.

The application system is used for biological and chemical experiments, such as multiple infusion switches for liquids and automated sequential reagent injection, which allows 12 or more solutions to be sequentially injected in a fully automatic manner using a computer-controlled 12/1 MUX dispensing bidirectional valve, a high-precision OB1 flow controller and intuitive ESI control software.

The system offers a large flow range (from 7 nL/min to 30+mL/min) and capacity (100µL to several liters).

A typical sequential fluid injection system uses a single pressure channel to inject multiple solutions into a microfluidic system in sequence. The MUX then dispenses rotary valves as selectors for easy fluid change, enabling quick switching and selection of liquids.

The OB1 flow controller, combined with an MFS or BFS flow sensor, enables very stable liquid injection (down to 0.006% of the flow rate). These operations can be performed using the ESI software interface. The software allows you to fine-tune flow parameters and automate your experiments with our intuitive scheduler.

Sequential fluid injection applications have the following advantages:

Large number of samples: Up to 12 or more solutions can be sequentially injected into the system

Stable pulse-free flow: Pressure drives the flow controller for stable fluid delivery and the most accurate results

High versatility: For many types of fluid systems, such as microfluidic chips, sensor test benches, flow chemistry configurations

Perform fast switching between fluid media: the switching time is less than 150 ms

Suitable for long-term experiments of small and large volumes: liquid capacity from a few microliters to several liters

Control pressure and flow simultaneously: provide versatility for your fluid injection

Wide flow range: from 7nL/min to 30+mL/min with accuracy as low as 0.2%

Design flow injection sequences: Create complex patterns and fully automate your system to test any operating condition in hours or days

Highly parallelized: Test multiple devices using a single setting

Software development kit: Use C, LabView, Matlab and Python to integrate into your platform.

Our sequential fluid injection systems are suitable for more complex experiments, such as using 20 or more solutions, removing bubbles, integrating into larger systems, or testing multiple chips/devices simultaneously.

Applications for sequential fluid injection include:

· Pressure and Flow Controller (OB1)

· Rotary Valve (MUX distributor)

· Microfluidic flow sensors (MFS) or high-precision BFS sensors

· Liquid storage pipe

· Partial pressure manifold

· Pipelines and connectors

· Software and SDK library (C++, Python, MATLAB, LabVIEW)

Options include:

· Additional pumping channels

· Additional flow sensors

· Microfluidic chip

· Computer

· Multiple manifold