Welcome to Dalian Leader Laboratory, a provider of laboratory solutions!

Service hotline: 0411-87307760

中文

中文

Welcome to Dalian Leader Laboratory, a provider of laboratory solutions!

Service hotline: 0411-87307760

中文

中文

CETONI high pressure syringe pump

一、 CETONI company

Germany CETONI was founded in 1991, focusing on the development and application of microfluidic injection pumps and laboratory automation products, the main products are high-precision injection pumps, flow control systems and modular, customized laboratory automation, including CETONI low pressure microfluidic injection pump, CETONI medium pressure injection pump, CETONI injection pump. CETONI high pressure/ultra high pressure injection pump, CETONI heating injection pump, as well as basic modules, stirring system, valves, syringes, software, collaborative robots, etc. With a flexible product portfolio, we can meet the diverse needs of customers and their processes, automate the experimental process and control the flow of microfluidics.

二、 CETONI syringe pump

1, CETONI low pressure syringe pump Nemesys S - precision syringe pump for microfluidic

Nemesys S Low Pressure Injection pump Features:

No pulsation; Continuous liquid transport; Flow range from pL/min to ml/min; Modular design; Easy to operate, easy to automate integration; Flexible valves and pressure sensors; Various types of glass syringes. Precise feeding for industrial applications, microfluidic control and microfluidic solutions in biology, chemistry.

Nemesys S uses a rigorous design of up to 178,000 steps /ml to improve dosing accuracy and flow uniformity, and with newly designed syringes, smart valves and flexible mounting brackets, can achieve multiple dosing tasks for microfluidic applications. The precise delivery of microliter and nanoliter liquids in the field of biology and biochemistry places greater demands on pump technology, requiring even flow rates and rapid changes in velocity. Optimal results can be obtained by optimizing the characteristics of CETONI injection pumps. The CETONI Elemnts software allows for intuitive control of the injection pump and easy automation of the liquid handling process through seamless integration.

2, CETONI medium pressure syringe pump Nemesys M-pressure up to 200bar

Nemesys S Medium pressure syringe pump Features:

High precision, no pulse, continuous flow, modular design; Suitable for medium pressure applications and viscous liquids up to 200Bar, high precision dosage and uniform flow for a variety of applications in the field of microfluidics.

Nemesys M medium pressure injection pumps and high pressure injection pumps with stainless steel syringes are designed to be safe, durable and easy to operate for demanding dosing tasks in research and industrial applications, especially microfluidics in fine and synthetic chemistry, as well as biochemical microfluidics and laboratory automation.

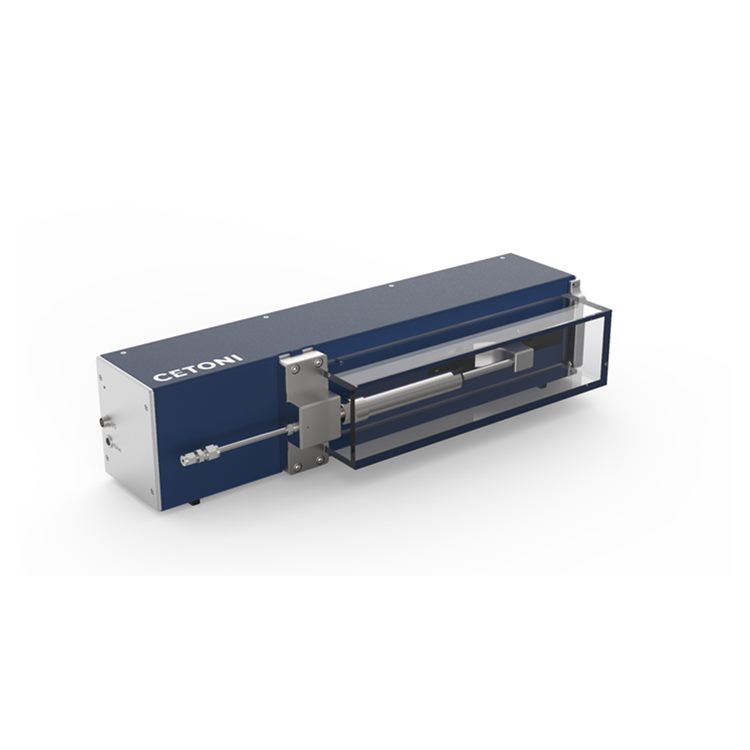

3, CETONI high pressure syringe pump Nemesys HPM- pressure up to 500bar

CETONI high pressure syringe Pump Nemesys high pressure module features:

Pressure up to 500Bar, flow up to 825ml/min; Nano upgrade high precision flow, continuous flow; No pulsation, pressure monitoring; Highly flexible for high pressure applications and viscous liquids.

The CETONI High pressure injection pump can be configured with 3ml-100ml volume syringes for liquid handling, gases and even supercritical fluids, and is suitable for high throughput applications and synthetic systems, as well as microfluidic processes in geology, petrology and mineralogy. An integrated pressure sensor and an additional protective cover made of polycarbonate provide additional security.

4, CETONI ultra-high pressure syringe pump Nemesys UHPM- pressure up to 890bar

CETONI ultra-high pressure syringe pump features:

Pressure up to 890bar; Flow rate up to 1.5L/min; No pulsation, compact design; Multi-purpose and extensible; Suitable for high and ultra high pressure and viscous liquid applications.

CETONI ultra-high pressure injection pump is suitable for high throughput and continuous liquid high pressure delivery, for example, for the study of oil or gas stored under the Earth's crust, the high precision and ultra-high pressure CETONI pressure injection pump is required, and its 7000N driving force can provide a pressure of up to 890Bar. In addition to high pressure applications such as test stands and high pressure containers, it is also suitable for dosage of viscous liquids in industrial processes, such as paints, lubricants and silicone, etc., suitable for production scale chemical synthesis, the use of 250ml syringes can obtain high precision, non-pulsating 1.5L/min high flow rate, which means that the annual output of tons of flow synthesis system is achieved with a small volume. Suitable for flow chemistry applications.

Thanks to its compact design and replaceable stainless steel syringe, the Nemesys UHP module can also be integrated into test benches or test systems as a flexible and easy-to-use instrument. The injection pump module has integrated safety couplings, valves and pressure measurement technology, making it a safe and reliable instrument

4, CETONI ultra-high pressure syringe pump Nemesys UHPM- pressure up to 890bar

CETONI ultra-high pressure syringe pump features:

Pressure up to 890bar; Flow rate up to 1.5L/min; No pulsation, compact design; Multi-purpose and extensible; Suitable for high and ultra high pressure and viscous liquid applications.

5. Base base of CETONI injection pump and NEMIX 50 liquid mixing syringe

The Base120 CETONI injection pump Base provides the basic interface for microfluidic setup for PC connection and power supply. The 120w power is mainly used for neMESYS injection pumps. For high-power requirements, such as controlling multiple injection pumps or additional Qmix microreaction components, the Base 600 can be used. The Base 120 can support 8 low pressure injection pumps, or 5 medium pressure injection pumps, or 2 high pressure injection pumps, and the Base 600 can support 41 low pressure pumps, 25 medium pressure injection pumps, and 12 high pressure pumps.

The NEMIX 50 syringe mixer is an integrated injection pump and liquid mixing unit with a large drive suitable for handling large volume syringes (100ml) in order to obtain high flow rates and high viscosity liquid delivery, which can effectively mix the contents of the syringe and is suitable for long-term administration.

Third, Germany CETONI injection pump and laboratory automation application field

CETONI microfluidic injection pumps and automation systems can be used in many fields:

(1) Biological field microfluidic: such as microdroplet preparation for the analysis of organisms in soil outcrops, bioprinting, microfluidic cell separation, high-throughput screening of microfluidic droplets, cracking and sampling of biological samples, etc.

(2) Microfluidics in geology, petrology and mineralogy: used for crude oil research and enhanced oil recovery.

(3) Liquid feeding in industry: feeding and coating systems for viscous liquids such as varnishes, lubricants and adhesives, flow chemistry and particle synthesis, etc.

(4) Chemical microfluidic: integration of automated liquid handling by collaborative robots, high-pressure injection pumps for liquid chromatography, synthesis of gold nanoparticles for flow control, microfluidic multi-electrode theory and application, automatic sample collection system, etc.

CETONI ultra-high pressure injection pump is suitable for high throughput and continuous liquid high pressure delivery, for example, for the study of oil or gas stored under the Earth's crust, the high precision and ultra-high pressure CETONI pressure injection pump is required, and its 7000N driving force can provide a pressure of up to 890Bar. In addition to high pressure applications such as test stands and high pressure containers, it is also suitable for dosage of viscous liquids in industrial processes, such as paints, lubricants and silicone, etc., suitable for production scale chemical synthesis, the use of 250ml syringes can obtain high precision, non-pulsating 1.5L/min high flow rate, which means that the annual output of tons of flow synthesis system is achieved with a small volume. Suitable for flow chemistry applications.

Thanks to its compact design and replaceable stainless steel syringe, the Nemesys UHP module can also be integrated into test benches or test systems as a flexible and easy-to-use instrument. The injection pump module has integrated safety couplings, valves and pressure measurement technology, making it a safe and reliable instrument in special fields and industrial environments.